At the Ohaaki power station in New Zealand, Intergroup was entrusted by Contact Energy with a critical task: desludging the site’s geothermal cooling towers. Over time, these towers accumulate large volumes of sludge that present both operational inefficiencies and serious safety risks especially due to the presence of hydrogen sulphide gas.

The Challenge

Traditional sludge removal methods in this environment required:

- Extensive use of PPE due to hydrogen sulphide

- High physical fatigue among workers

- Large crews (up to 9 people)

- Time-consuming and inefficient operations

In short, manual cleaning posed high risks to workers and significant downtime for the plant.

The Smart Solution

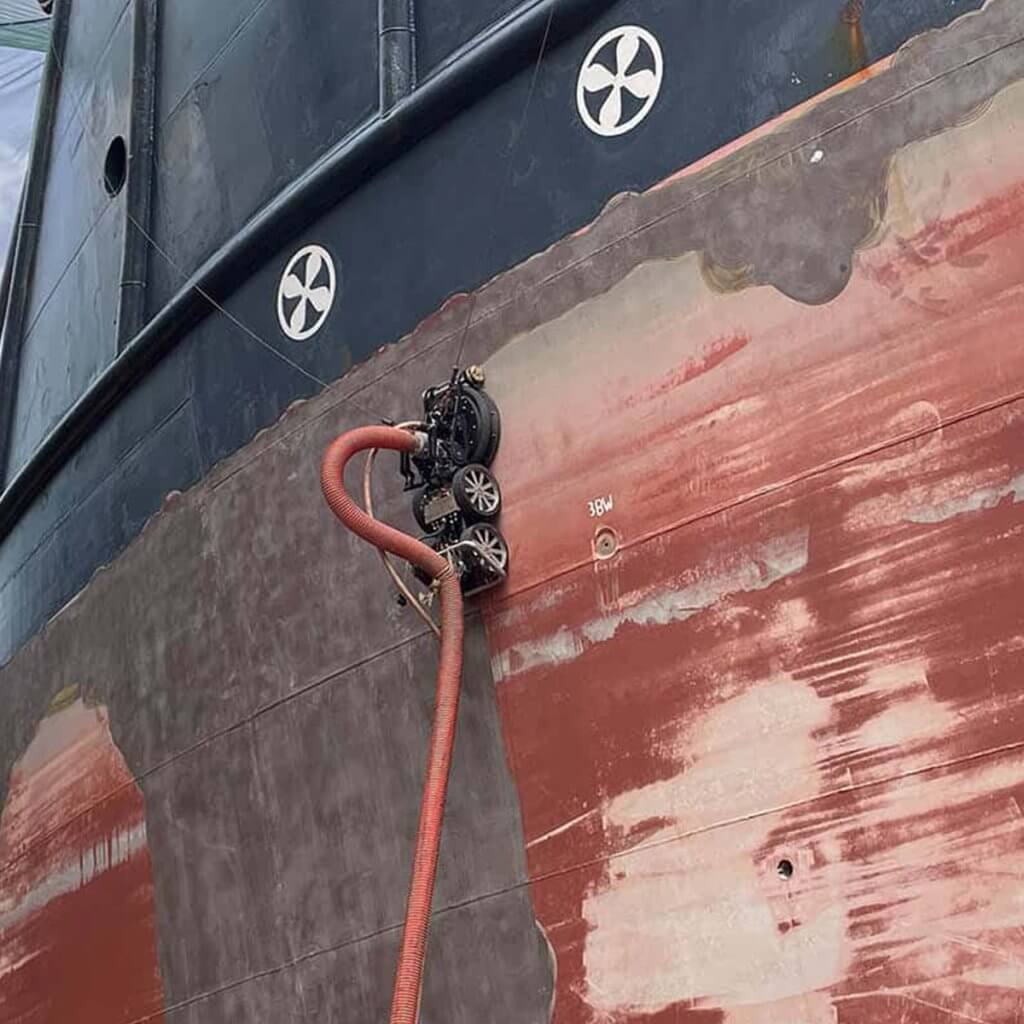

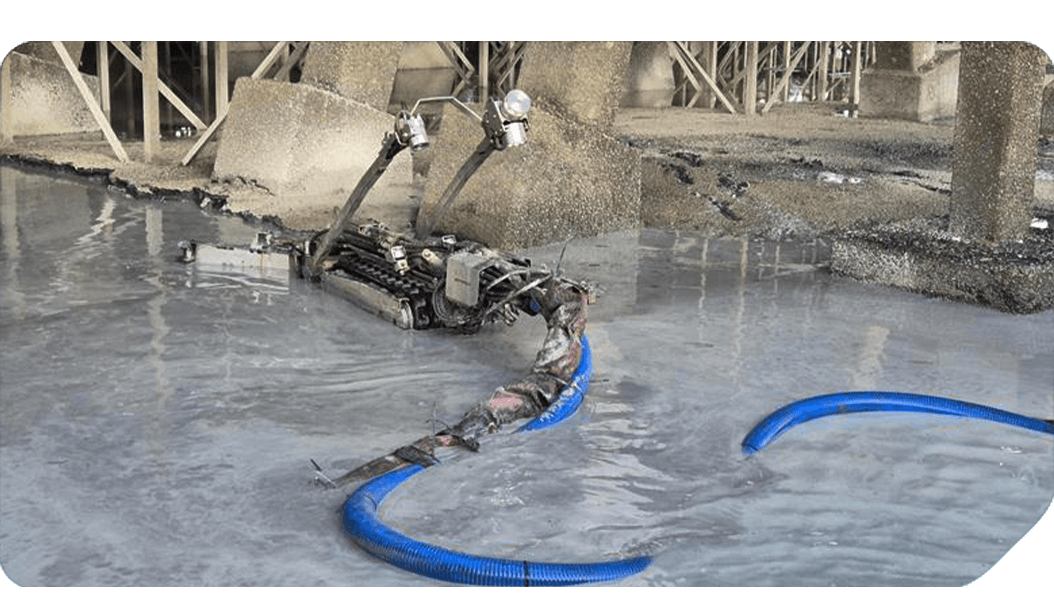

Thanks to our official distributor KOR Equipment Solutions, Intergroup deployed the Gerotto Lombrico S, a Zone 0 certified No-Man entry robot specifically designed for tank cleaning and confined space operations. This remotely operated robot can be customised with various interchangeable tools, such as cameras and lights, nozzles, augers, and squeegee tools, all to improve the removal of sludge and enhance the cleaning of tank bottoms.

Key benefits of the robotic solution:

- Fully remote-controlled and intrinsically safe

- Reduced crew from 9 to just 3 operators

- Continuous operation

The Results

Over a 10-shift operation, Intergroup achieved:

- Tripled productivity compared to previous manual efforts

- Up to 40 cubic metres of sludge removed per shift

- Significant reduction in safety risks and PPE requirements

- Lower fatigue, faster turnaround, and improved sludge management

The Gerotto robot not only improved safety, it revolutionised the efficiency of the desludging process. As soon as the sludge was collected, it was mixed with lime and pre-treated, making it safe to transport and handle by the time it reached Auckland.

Robotic cleaning is not just the future. It’s happening now.

Discover more about our robotic solutions for high-risk industrial environments.

Articles and news

Latest articles

Subscribe to the newsletter to stay updated on the latest news