Accessori

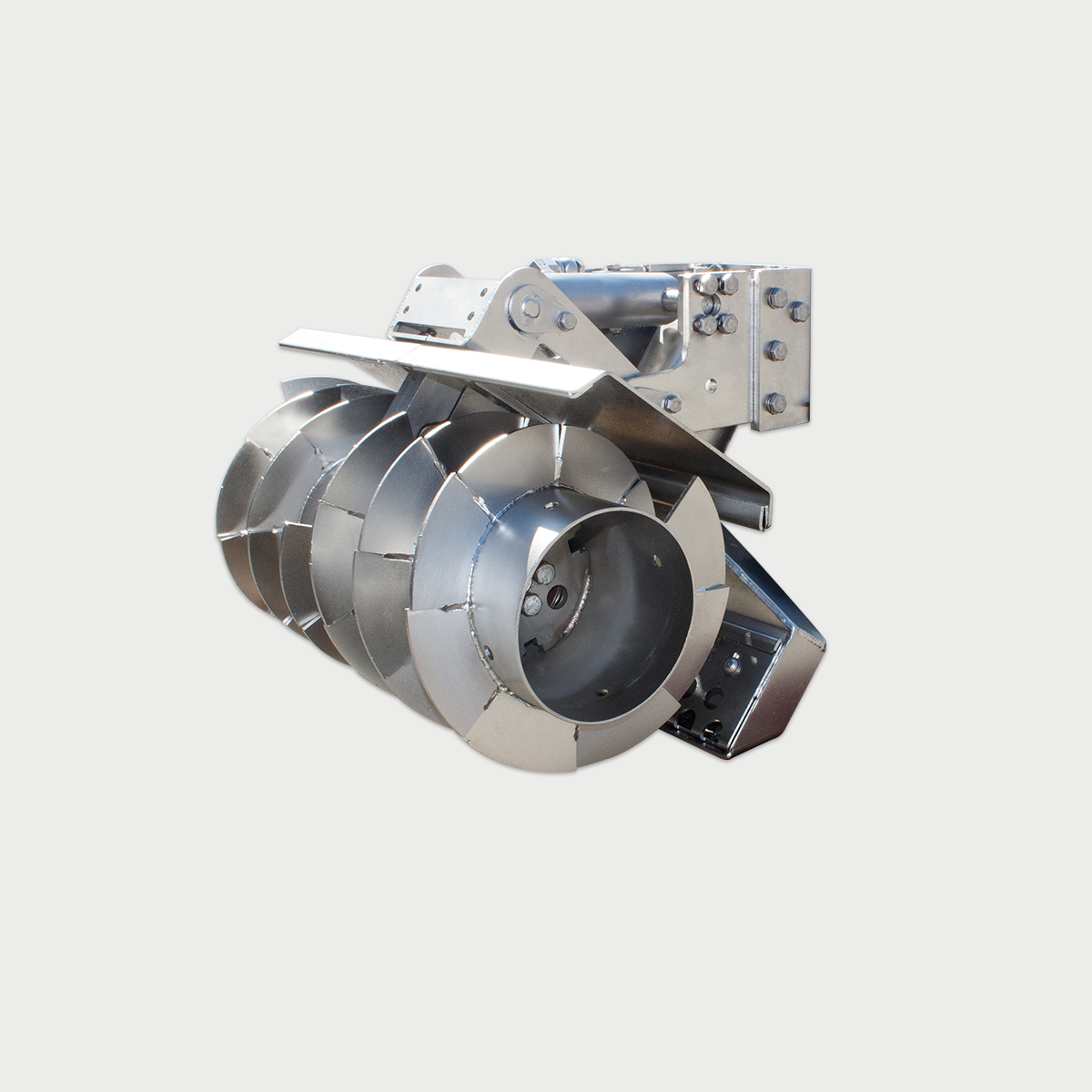

Augers

Gerotto’s research and development team I thought of different types of front augers: bronze for removing material in ATEX zone 0, toothed for the toughest material, and brushes for conveying gravel or dust to the suction pipe. Discover the accessory that best suits your needs.