The UNI PDR 177:2025 Reference Practice entitled “ Low-environmental-impact maintenance and material removal in confined spaces and explosion-risk areas – No-man entry robotic technologies” has been published.

This is a fundamental document that introduces rules and definitions for a rapidly evolving sector: that of remote-controlled robotic technologies for maintenance and remediation in high-risk environments.

A document that describes innovative solutions for the removal of materials in confined spaces and ATEX zone 0

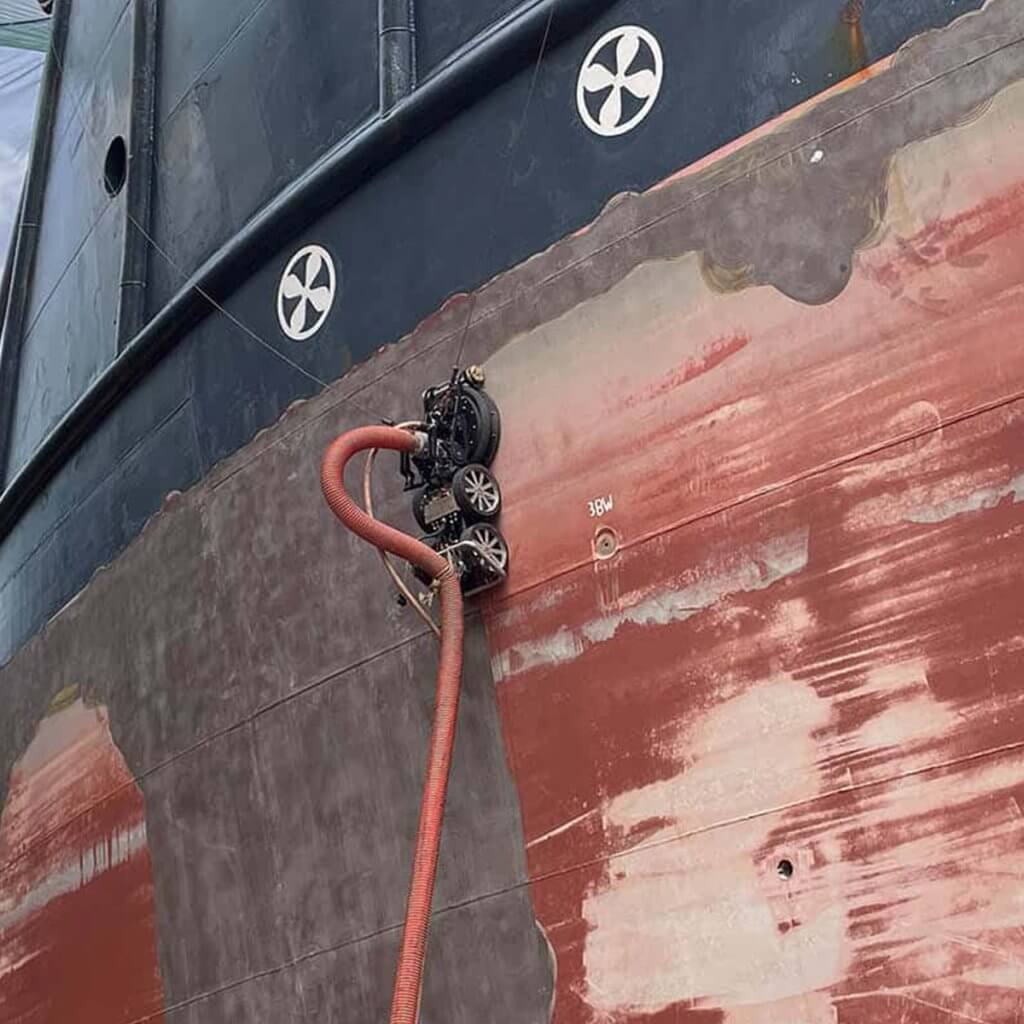

Historically, the cleaning and remediation of tanks, vats, and pipes were manual activities fraught with high risks, especially in the presence of potentially explosive atmospheres. With the advent of remote-controlled robots (no-man entry robots), site safety has increased significantly, thanks to the possibility of eliminating direct human entry into confined spaces and ATEX areas.

PDR 177:2025 is the first technical document to define and classify these technologies, filling a regulatory gap and offering clear guidance to manufacturers, operators, and end users.

Who it is aimed at

The practice is designed as a reference tool for:

- designers and management bodies

- multi-utility companies and plant owners

- contractors and operators

- those responsible for maintenance, industrial cleaning, safety, and HSE

Numerous sectors are involved: oil & gas, chemical, pharmaceutical, nuclear, civil and construction, water treatment, and biogas.

Types of robots

The document provides a definition of no-man entry robots and divides them into nine categories, including:

- suction robots

- robots for ATEX/IECEx zone 0

- robots with on-board pumps

- robots for excavation and material handling

- underwater robots

- robots for video inspections

- robots for milling

- robots for surface processing

- robots for surface cleaning

Each type is described based on its technical characteristics, power supply, suction or pumping capacity, and operating conditions.

Practical applications

These machines are used in a wide range of activities:

- tank cleaning in refineries and chemical plants

- removal of solid materials and contaminated soil

- video inspections of sewers and aqueducts

- controlled milling and hydro-demolition

- cold cutting and high-pressure cleaning

- remediation of high-temperature furnaces

- cleaning of fire tanks and pipes with pigs

Safety and sustainability

PDR 177:2025 is part of Italian and European legislation that focuses on safety and the reduction of accidents at work.

The adoption of these technologies not only protects the safety of operators, but also contributes to environmental sustainability by improving waste management and reducing the impact on the territory.

⬇️ DOWNLOAD THE PRACTICE HERE ⬇️

Articles and news

Latest articles

Subscribe to the newsletter to stay updated on the latest news